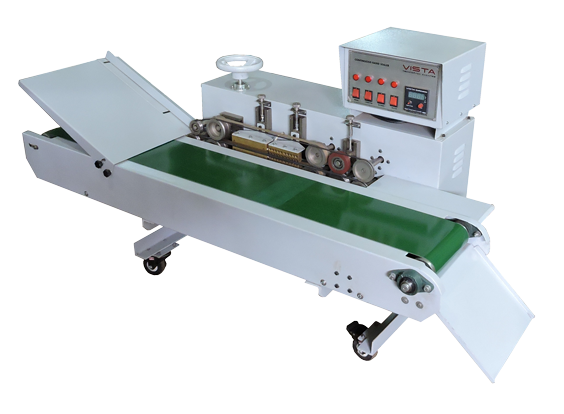

Automatic Sealing Machine

Automatic Sealing Machine

Enquiry Now

Introduction of Automatic Sealing Machine

The automatic sealing machine is a highly efficient and versatile piece of equipment designed to automate the sealing process for various types of packaging, including bags, pouches, trays, and containers. With advanced technology and precision engineering, this machine offers fast, reliable, and consistent sealing performance, making it an essential tool for industries requiring high-volume production and stringent quality control.

Technical Specifications of Automatic Sealing Machine

-

Sealing Mechanism: Utilizes advanced sealing mechanisms such as heat sealing, impulse sealing, or ultrasonic sealing, depending on the packaging material and application.

-

Sealing Speed: High-speed sealing capabilities to accommodate high-volume production requirements, with adjustable speed settings for optimal performance.

-

Sealing Width: Accommodates different sealing widths, allowing for sealing of various package sizes and configurations.

-

Sealing Temperature: Precise temperature control for consistent and uniform seals, ensuring product integrity and quality.

-

Sealing Pressure: Adjustable sealing pressure settings to create strong, airtight seals without damaging the packaging or product.

-

Control System: Equipped with user-friendly controls and programmable interfaces for easy operation, setup, and monitoring.

-

Integration Capabilities: Can be integrated into existing packaging lines or operated as a standalone unit for seamless production flow.

-

Safety Features: Incorporates safety interlocks, emergency stop buttons, and protective guards to ensure operator safety during operation.

Features of Automatic Sealing Machine

-

Fully Automated Operation: Automatically feeds, seals, and cuts packaging materials without the need for manual intervention, maximizing production efficiency and reducing labor costs.

-

Advanced Sealing Technology: Utilizes state-of-the-art sealing mechanisms and control systems to deliver precise, consistent, and reliable sealing performance.

-

Multi-Functional Sealing: Offers versatility in sealing options, including straight-line seals, crimp seals, and serrated seals, to accommodate different packaging formats and requirements.

-

Customizable Settings: Allows for adjustment of sealing parameters such as temperature, pressure, and dwell time to achieve optimal seal quality for various packaging materials and products.

-

High-Speed Performance: Capable of sealing hundreds or even thousands of packages per hour, ensuring rapid throughput and minimal downtime.

-

Integrated Quality Control: Includes built-in sensors and inspection systems to detect and reject packages with incomplete or faulty seals, ensuring product integrity and compliance with quality standards.

-

Remote Monitoring and Diagnostics: Enables remote access and monitoring of machine performance, with real-time alerts and diagnostic tools for proactive maintenance and troubleshooting.

-

Modular Design: Features a modular construction with interchangeable components and tool-less adjustments for easy maintenance and quick changeovers between different packaging setups.

Benefits of Automatic Sealing Machine

-

-

Increased Productivity: Automates the sealing process, maximizing production throughput and minimizing manual labor requirements.

-

Improved Efficiency: Ensures fast, precise, and consistent sealing, optimizing operational efficiency and reducing production costs.

-

Enhanced Product Quality: Creates strong, airtight seals that preserve product freshness, extend shelf life, and prevent leakage or contamination.

-

Compliance and Traceability: Facilitates compliance with regulatory requirements and quality standards, with built-in inspection and traceability features.

-

Versatile Application: Suitable for sealing a wide range of packaging materials, including plastic films, laminates, aluminum foils, and composite materials.

-

Cost Savings: Helps reduce packaging material waste, minimize product losses, and lower overall operating costs, resulting in improved profitability and ROI.

-

Scalability and Flexibility: Can be scaled up or customized to meet evolving production needs and accommodate new product lines or packaging formats.

-

Brand Reputation: Enhances brand reputation by delivering consistently sealed packages that meet consumer expectations for quality, safety, and reliability.

-

Applications of Automatic Sealing Machine

The automatic sealing machine is utilized across various industries and applications, including:

-

Food and Beverage: Sealing of packaged foods, snacks, beverages, and ready-to-eat meals in retail, catering, and food service sectors.

-

Pharmaceuticals: Sealing of blister packs, pouches, sachets, and vials containing medications, tablets, capsules, and medical devices.

-

Cosmetics and Personal Care: Sealing of tubes, bottles, jars, and sachets containing creams, lotions, gels, and beauty products for retail and distribution.

-

Industrial and Manufacturing: Sealing of bags, pouches, and containers containing chemicals, powders, granules, and industrial components in manufacturing and logistics.

-

E-commerce and Logistics: Sealing of parcels, packages, and shipments for online retail, logistics, and fulfillment operations.

Conclusion

Frequently Asked Questions (FAQs)

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072